Enterprise dashboard platform with custom driver toolkit and DVR-style historian playback across 40 production lines.

Industry: Plastics Manufacturing

Quick Facts

| Attribute | Value |

|---|---|

| Production Lines | 40 across 5 facilities |

| Clients | ~80 concurrent web/desktop dashboards |

| PLC Connectivity | Custom driver (Tatsoft Driver Toolkit) |

| Historian | Prediktor APIS Historian Connector |

| Database | ODBC_DSN and SQL Server |

| Architecture | Load balanced with single URL access |

The Challenge

Challenge: Replace older, custom-built dashboards that were difficult to maintain, limited in scalability, and disconnected from ERP and historian systems.

Specific pain points:

- Legacy dashboards difficult to maintain

- Limited scalability for growing operations

- Disconnected from ERP and historian systems

- No standardized, unified view of production KPIs across multiple plants

- Could not easily adapt to new production lines or evolving requirements

- Operators lacked consistent visibility across facilities

Impact: Without unified dashboards, operators could not efficiently monitor production KPIs across plants, and the system could not scale with business growth.

The Solution

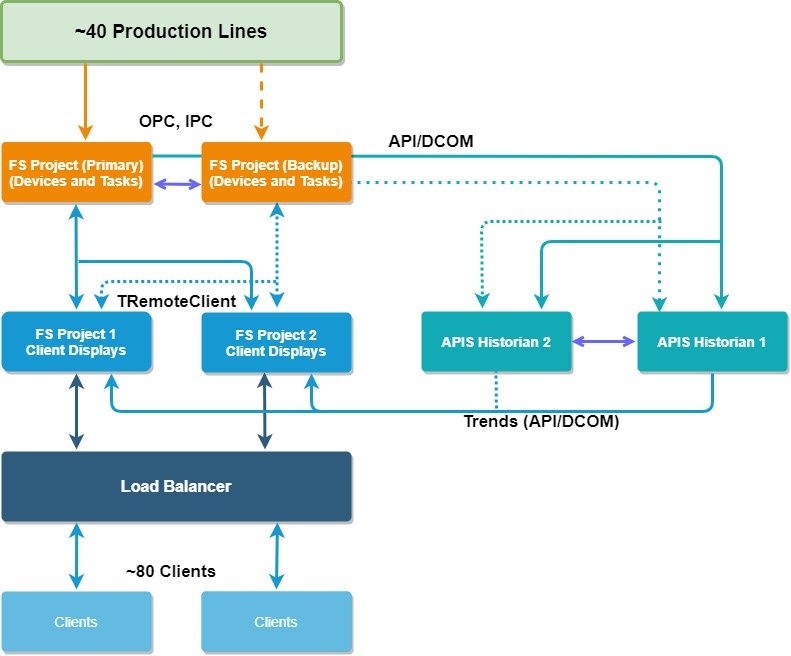

Architecture

| Tier | Component | Capabilities |

|---|---|---|

| Field | Proprietary blown film machines | Custom driver via Driver Toolkit |

| Historian | Prediktor APIS | Trending, DVR playback |

| Database | SQL Server (ODBC_DSN) | Centralized MES data model |

| Central | FrameworX Enterprise | Dashboards, ERP integration |

| Load Balancer | Single URL access | Redirects based on connection count |

| Clients | ~80 concurrent | Web and desktop dashboards |

Scale

| Metric | Value |

|---|---|

| Production Lines | 40 |

| Facilities | 5 |

| Concurrent Clients | ~80 |

| Dashboard Levels | Company / Plant / Line |

Dashboard Hierarchy

| Level | Scope |

|---|---|

| Company | Enterprise-wide KPIs |

| Plant | Facility-level monitoring |

| Line | Individual production line detail |

Key Technical Features

| Feature | Description |

|---|---|

| Custom PLC Driver | Built with Tatsoft Driver Toolkit for proprietary machines |

| Dynamic Templates | Line template self-adjusts based on number of film layers |

| Reusable Symbols | Rapid deployment across all lines and plants |

| DVR Playback | Historian-backed video-style process replay |

| Load Balancing | Single URL with automatic connection distribution |

Data Integration

- ERP system connectivity

- Historian trending and analysis

- Manual input integration

- Real-time machine data

Key Enablers

FrameworX capabilities that made this solution possible:

| Capability | Application |

|---|---|

| Custom PLC Driver | Driver Toolkit enabled proprietary machine connectivity |

| Dynamic Templates | One template self-adjusts for varying film layer counts |

| Reusable Symbols & Screens | Rapid deployment of company/plant/line dashboards |

| SQL MES Integration | Centralized data model streamlined multi-plant rollout |

| Historian Connectivity | APIS Historian for detailed trending and DVR playback |

| Real-Time Operations | ERP, historian, and manual input unified in dashboards |

The Results

- Replaced Legacy Dashboards — Scalable enterprise platform replaced difficult-to-maintain custom systems

- Standardized KPIs — Unified dashboards across 40 lines and 5 plants

- Reduced Engineering Effort — Reusable symbols and templates accelerated deployment

- Unified Data View — ERP, historian, and machine data visible together in real-time

- Improved Troubleshooting — DVR playback enables detailed process analysis

- Future-Ready Platform — Capable of expanding with new lines and requirements

- Load Balanced Access — Single URL for ~80 concurrent users with automatic distribution

This case demonstrates enterprise dashboard deployment with custom driver development and historian-backed DVR playback for plastics manufacturing.

In this section...

Overview

Content Tools

Tasks