This page presents the FrameworX Modules that implements its core functionality.

Modular Architecture

FrameworX’s modular architecture allows you to create in one environment and deploy what you need, to where you need it — from Server functionally to Edge.

The platform includes a complete set of Rapid Application Development tools.

FrameworX Modules

FrameworX modules are organized to deliver a simple way to encapsulate all the functionalities required when creating real-time industrial applications, from Edge to SCADA HMI and Enterprise systems.

| FrameworX Modules | |

|---|---|

| Module | Description |

| Creates the Real-Time data model, including Tags and Templates. Dynamic tag-less on-demand data connectivity with external system is possible by the Dynamic TagProvider. The Asset modeling enables the creation of hierarchical view of the data. | |

| Core Modules | Stores and retrieves time-series data. SQL historian engine is included in the platform, as well as Canary Historian at no extra charge. Seamless integration with concurrent other historian tools, such as OSIsoft PI and InfluxDB. Out-of-the box store and forward functionality. |

| Core Modules | Manages access control to the project configuration and security model to the user of the running project. User security allows FDA compliance applications, Active Directory integration, LDAP and much more. Easily define which display/objects are accessible based on the user profile and security groups. |

| Core Modules | Includes more than 50 native communication protocol drivers to PLC, transmitters and field devices. Support OPC UA and DA, server and client execution, and new industry standard like MQTT SparkPlug B. |

| Core Modules | Organizes the Tags around Groups and Areas, allowing an easy definition for Alarm conditions, Audit-Trail, email or SMS or voice notification, online and historian alarms visualization. Agnostic storage on any selected Database provider. |

| Core Modules | Manages multiple simultaneous connections with SQL database, processes to queries and tables customized for the values of real-time tags. Manages recipes and data files in ASCII, UNICODE or XML. |

| Core Modules | Delivers high performance server-side and client-side scripting capability. Programming languages includes C#, VB.NET, Python and JavaScript. Easily create multi-threading application, with parallel execution for the task, add references to externally developed classes. |

| Core Modules | Creates Text, PDF or HTML5 reports with no needing of any external tool. |

| Core Modules | State of the art drawing tool to create User Interface Displays, with extensive set of fully customizable Symbols and Graphical components. Create Responsive Dashboard, as well as traditional Process Diagram or SCADA Hight Performance Graphics. Deploy the displays in HTML5, or secure .NET SmartClient, to desktop mobile or web clients. Extend the user experience with advanced features, including Language Location, Engineering Units dynamic conversion, and Displays dynamic chame of Theme colors. |

| Diagnostics Tools | Delivers tools specifically designed to assist on the commissioning of the applications, long maintenance, and development tests. Leverage the 3 decades of experience in start-up and factory-floor realtime systems. |

Tags, Assets and Templates

Tags, Assets and Templates

TAT and Real-time Elements

Tags, Assets, and Templates are the core components to real-time data modes and are the power of our platform. Our company name, Tatsoft, even has Tags, Assets, and Templates built into it. The FactoryStudio system has a built-in, real-time, event driven, in-memory database, that manages tags, assets, and events.

Real-time Tag Types

A typical HMI-SCADA system has only basic tag types, such as numeric and message tags. As FactoryStudio targets IT and MES systems, it goes far beyond basic tag types and supports real-time entities that match every SQL type and many .NET Framework entities, including Images and a complete DataTable in a single real-time tag.

Assets and Categories

Organize your project with categories and assets. An asset is composed of tags and other application objects connected to your process hierarchy. FactoryStudio allows implementation of ISA 95 modeling specifications, which can be essential in large systems.

Templates

Templates are user-defined structures, similar to .NET classes, that allow composition and hierarchy. Besides the built-in basic types, real-time tags can be created based on templates that reflect physical assets, which speeds up and simplify the application development.

Tag Historian and Trend Charts

Tag Historian and Trend Charts

Store and Forward on Edge HMI and Edge Gateway applications

Universal Time and Daylight Saving

These features, as described for the Alarm and Events, are also available for the Tag Historian database management.

Process Analysis and Batch Systems

Compare two curves on the same chart from two different start times, ideal for batch and process analysis.

Vertical and XY plots

Vertical waterfall and XY charts are available, with all properties accessible through real-time tags or in the code behind scripts.

Annotations and Alarms Overlay

Customizable open project templates are provided, so you can overlay annotations stored in SQL databases, or alarm conditions and acknowledgement, on top of the trend charts.

Combine Historian curves with any SQL database queries. |

Real-time Online Charts

Online charts run at the client display level, even if there is no historian to the selected tags. Built-in trend chart control is available for desktop, web and mobile clients.

Customize and Save at Runtime

Empower operators to customize tag groups, scales and the whole appearance of the trend charts at runtime; save and share the configuration.

Snapshots, Tables and Reports

Trend charts can be added to web and PDF reports, image snapshots and value data table exports are available upon operator commands or any process event.

Built-in Canary Historian |

OSIsoftTM PI System Database

For high-performance, large applications, instead of a SQL database, the tag historian can be kept on the PI System database. The pure .NET SDK level connection with PI (no COM, OPC or OLEDB required) provides high performance and single-click tag definition synchronization.

Data Quality and Timestamp

Tag Quality is stored and presented on the trend charts. FactoryStudio is able to handle up to 0.1 ms interval timestamps, therefore, the precision will be whatever the evolution of networks and data acquisition devices will bring in the future. Your data management based on FactoryStudio is prepared for long-term usage and process enhancements.

Real-time SPC calculation

<<<<. should we add a definition here?>>>>

Security and Redundancy

Security and Redundancy

Redundancy switch time and high volume data was tested to meet rigorous offshore requirements. |

Group and User Permissions

Total flexibility to define privileges based on groups or specific users. Permissions can be global or tied to a specific display, object, or input action.

Runtime Users

Dynamically create users and store credentials in SQL databases. Get users from Active-Directory or third-party system for integrated security or unified login.

User Policies

Identification policies, session duration, control, automated logoff, e-sign, audit-trail, and a complete set of user management features are available.

FDA and NERC Regulated Applications

Our platform allows delivering applications in compliance with Title 21 CFR Part 11, and it was designed following the applicable recommendations from NERC, such as the CIP- 007-1-Cyber Security-System Management.

Security at the Core Level

Security must be implemented at the core, not applied externally. FactoryStudio modules have built-in security related components designed from the core.

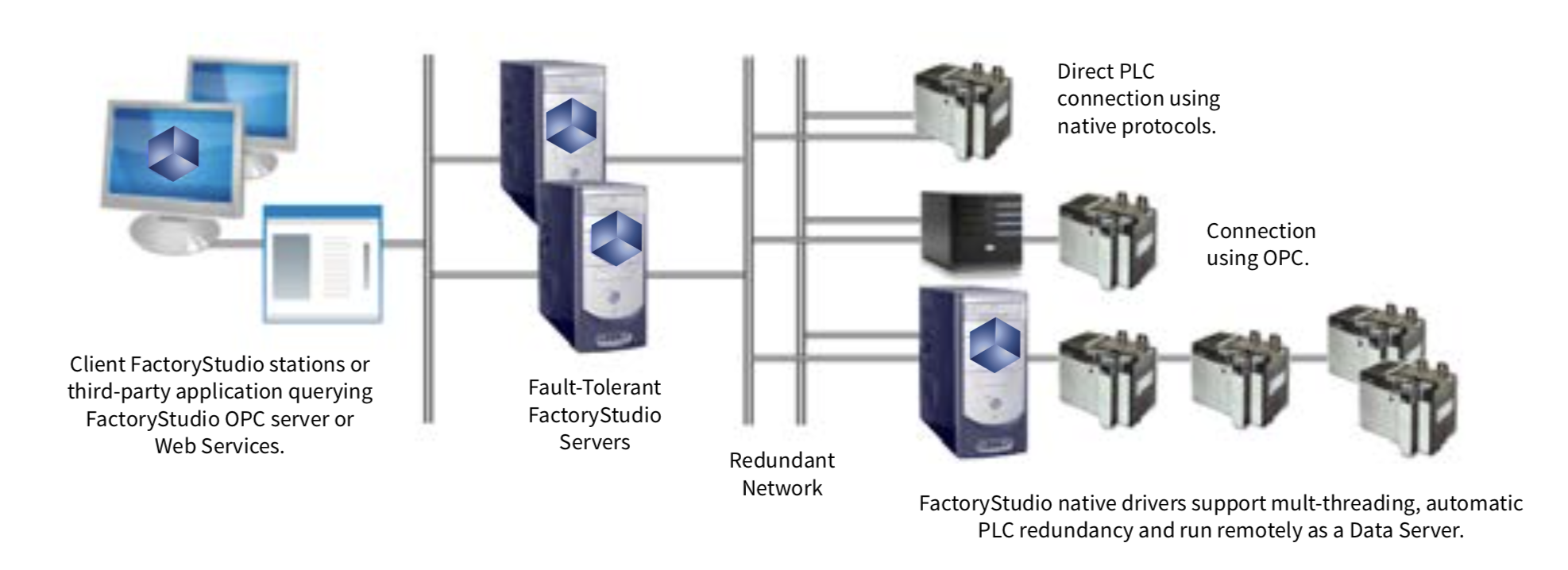

Hot-standby Fault-tolerant Servers

FactoryStudio automatically initializes and continues to synchronize the primary and secondary server. The Device communication channels are also easily setup for redundant physical networks and redundant PLC nodes.

Database Redundancy

The Alarm and Historian database can be assigned to a third-party external cluster or replicated automatically when running on the FactoryStudio servers.

Project Configuration Synchronization

Engineering tools provide features to simplify configuration and updates in redundant scenarios.

Hot-swapping

Redundant or stand-alone servers allow dynamic switching of project versions, without interrupting service for connected clients and keeping the real-time database loaded.

Redundancy at the Core Level

Real-Time tags, Devices, Alarms, Historian, Scripts, Clients, all FactoryStudio's modules, were designed from the ground up to meet redundancy and hot-swapping requirements.

Devices and Protocols

Devices and Protocols

Native Communication Drivers

Connectivity is a FactoryStudio's key feature. We include a wide variety of industry standard protocols, and we enable built-in communications with PLCs, historians, databases, and other devices. New drivers are continuously being added, and our SDK makes it easy to add any additional drivers that may not already be included.

OPC Client and Server Support

The platform is in full compliance with the OPC Server and Client specifications. For any protocol not included with the product, the OPC client provides all the necessary integrations.

Remote Data Servers

Drivers, native or OPC, and data acquisition can run on remote computers to do things such as retrieving data from RS-232 devices or eliminating the requirement for DCOM OPC configuration.

OPC Data Server FactoryStudio Station

FactoryStudio can be deployed as a stand-alone OPC Data Server that uses native protocols and provides data to other systems through its OPC Server interface.

Automatic Synchronization

A Tag Import Wizard and automatic definition synchronization is provided for OPC Servers, Rockwell ControlLogix L5K files, CSV files, Beckhoff TwinCAT, OSIsoftTM PI System, and PI AFTM; new wizards are continuously being added.

FactoryStudio performs real-time optimization, blocking addresses to maximize the use of the communication channel. |

Process Isolation and Multi-threading

Data communication runs in its own .NET domain, with a WCF layer to isolate the drivers from the main real-time database. For maximum performance, multiple threads are created for each protocol and device node.

Diagnostics Tools

A complete set of testing, deployment, and diagnostics tools provides fast and reliable application development and installation.

Built-in Performance Monitoring

Statistics are generated to help with troubleshooting and the fine tuning of high performance applications. Some of the performance related statistics gathered include: system messages, success and error messages, dynamic block creation, and cycle time and execution time on each block.

Dynamic Addressing

Everything in the driver configuration, from the station node IP to address and tag mapping, can be changed online using the project script. Standard applications that have the runtime setup to specific conditions for where it is being deployed can be created.

Extensive Communications Drivers Library

See Communication Drivers section. |

Alarms and Events

Alarms and Events

Real-time Alarm Processing

The Alarm module was created on pure .NET managed code, with multi-threading and exception control, for maximum performance and reliability. Combining the Alarm, Dataset and Script modules, you can log and bookmark process execution events, like downtime, startup, shutdown, batch control and continuous process analysis.

Storage and Replication

Alarm Historian data can be saved in any local or remote SQL database. When using redundancy, automatic synchronization of the database is provided. The replication guarantees the accuracy of the exact same data on both servers, even when they are using different providers.

OSIsoftTM PI EFTM Event Frames

The system also has a seamless, SDK level, connectivity with PI BatchTM and PI EFTM for data presentation, charts and custom data management.

Universal Time and Daylight Saving

FactoryStudio leverages UTC (Coordinated Universal Time) on all logging and online date time objects; so that Alarms, Events and Historical data are accurately time stamped for when they happened, no matter where you are located or any daylight saving settings.

Audit Trail and Alarm Areas

One-click configuration to enable audit trail on Operator Actions, Database and Reports Events, User logon and logoff, System events and custom tags events. Data is archived in SQL tables with project defined encryption.

Alarm Visualization Component

Whether on a PC, web browser, or iPad, a built-in graphical visualizer for alarms is provided.

Filtering, SQL queries, grouping, printing, saving, acknowledging and exporting are some of the built-in features included.

Notification Subscription

Project scripts, with access to the entire Microsoft .NET Framework, can subscribe to alarm events to implement custom actions, such as notification and calculation methods.

Store and Forward

When using remote databases, a store and forward option is provided, so a local cache is created, while the connection is not available and forwards the data when the database connection is reestablished.

Localization

Online messages and query results from the Alarm Historian database can be translated on the fly to local languages based on automated dictionaries.

Unlimited number of alarm conditions are allowed for each tag. |

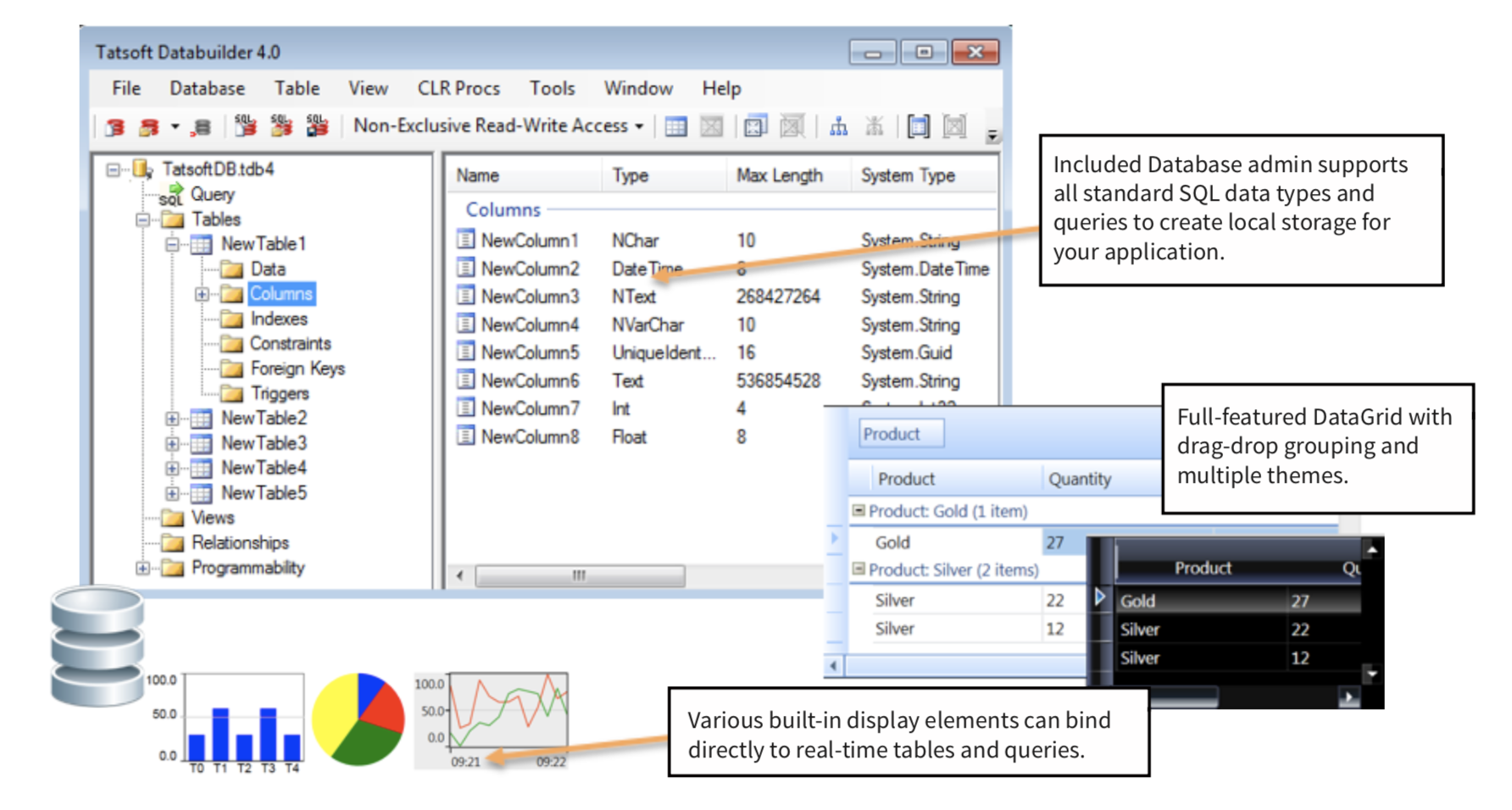

Datasets and SQL

Datasets and SQL

Real-time Queries and Tables

Any data source with ODBC, OLE-DB, or ADO. NET support can be connected with the application. An easy syntax allows you to create or customize any query or table search with real-time tags.

Client-Server Architecture

Real-time queries can be processed either from the server or from the client computer, asynchronously or synchronously. To achieve a better performance, multiple requests from distributed clients are cached and synchronized in the server.

Multiple Database Connections

FactoryStudio provides seamless integration with any third-party database, including Microsoft SQL Server, Oracle, MySQL, Informix, SQL Lite, PostgreSQL, and others.

Data Gateway

Connecting client queries through Firewall protected security zones, such as moving data between the Automation Network and the IT network, is no longer an issue. FactoryStudio provides a built-in firewall friendly data gateway. Data queries from clients are routed in a secure way through any FactoryStudio system.

Advanced DataGrid

Our platform provides a fully-featured DataGrid object that presents tables and queries from databases, as well as shows the contents of any tag, assets, or real-time objects. Drop the table, query, or tag in the Grid Data Source to create front-end visualization, edit any real-time object, or edit any database.

Scheduling and processing recipes and real-time data consolidation is made easy. |

Scripts and .NET

Scripts and .NET

Built-in Code Editor

FactoryStudio includes an integrated script editor for developers to create custom functionality for their application. The editor provides a powerful set of tools to help you test and evaluate your scripts. Debugging tools include assigning breakpoints, stepping into code, stepping over code, executing line by line, and watching values of objects change with each step.

Scripts are executed natively as managed code within the .NET framework, meaning you cannot create a script that would inadvertently cause the system to shut down. This provides a greater level of security and up-time for your application.

Server and Client Domains

Using the FactoryStudio script editor, you can create scripts that execute on the server for a global reach, or they can execute on the client side for a local reach.

Tasks, Classes and Expressions

You can create Tasks, .NET classes, and function libraries. In some cases, it may be more efficient or desirable to create one-line expressions, rather than full methods. For that purpose, FactoryStudio provides an expression editor that allows access to all .NET operands and classes.

Object Orientation, Project Elements

All project elements, including Tags, Datasets, Alarms, devices, and a status of communications, are immediately accessible via IntelliSense. Since they are native .NET objects, no temporary tag calls are required. With a single operation, you can move data from Tags to .NET external Data-tables.

C#, VB.NET and Code Translation

FactoryStudio includes industry standard languages of C# and VB.NET. Engineers no longer have to suffer through using old proprietary, single-threaded, or interpreted scripting editors. Translate your code between C# and VB.NET anytime to better leverage your expertise.

Events and Scheduling

Tasks and expressions can be triggered to execute by date, time, condition, calendar, tag change, or interval. Execution is distributed among processes, each running in its own application domain and isolated from the real-time database, for maximum system security and performance.

Online project changes and configuration can be done while running and debugging. |

Reports and Data Access

Reports and Data Access

Built-in Report Designer

FactoryStudio includes a user-friendly simple Report layout editor integrated with the engineering workspace. The rich text format uses underlying XAML flow document technology from WPF, Windows Presentation Foundation; that enables the inclusion of graphics and flexible formatting.

Runtime Display Snapshots

The runtime displays can be opened in background or saved to image files, allowing you to create rich graphic snapshot reports. Current displays and layouts can also be printed or saved as an image to disk.

Report Append and Text Data Logging

The report generator ability to append files, based on the project configuration and real-time tags, can be used to create CSV and text logging files for scenarios that require the information to be created as time goes by, such as batch reports and shift reports.

Reports can be saved in multiple formats: Text (ASCII or Unicode), HTML and PDF. |

Built-in Report Designer

FactoryStudio includes a user-friendly, simple report layout editor integrated within the engineering workspace. The rich text format uses underlying XAML flow document technology from WPF that enables the inclusion of graphics and flexible formatting.

Dynamic Graphical Symbols

Any symbol from the real-time displays can be included in the Report. The dynamic behavior of the symbol, such as color, text output, and rotation, are all updated using the current tag values when generating the report. User controls such as Trend and Bar charts can be added as well.

Tables and Queries

The contents of database tables and queries can be added to the reports. The queries and report generation execute in isolated processes, not interfering with the real-time processing.

Data Access Toolkit

A complete .NET Data Access library is available to create custom reporting solutions or to integrate with Microsoft Office, SQL server reporting services or other vendors tools. A COM model API is also available to be used from Excel VBA and JavaScript applications.

Graphical Displays

Graphical Displays

Advanced Graphical Technology

FactoryStudio is the first complete product where all configuration and execution tools are pure Windows Presentation Foundation (WPF), the latest graphical technology from Microsoft. WPF uses the full potential of the current graphics cards and computers, providing superior quality and performance.

Dynamic 3D Models

Connect real-time tags to control properties in 3D models created with 3DMax or other systems that supports the .3DS extension.

Smart Symbols

Smart Symbols are asset and template-based reusable graphical components, with runtime dynamics or static binding and centralized management. The symbols keep a live link with the library, which means you only need to modify the symbol once and it will automatically apply to all displays.

Code Behind and Expressions

Develop code behind using C#, VB.NET, or HTML5/Javascript, expressions on dynamic animations, or client-side event-driven scripts.

Touch Panel Applications

Customizable on-screen keyboard, multi-touch support, momentary buttons, and other features deliver rich touch panel systems.

Unique set of Dynamic Animations

Unique new dynamics, such as opacity, shine and skew, combined with move, scale, color change, rotate, and others, applied to any object, provide the most comprehensive set of animations. No more difficult laborious workarounds dealing with drawing tools created on top of legacy graphics systems.

Images, Colors and Transparency

Images are added to the project database for centralized management. Low and hi resolution versions of the image are automatically created, optimizing the project. Transparency, alpha color, image brushes, and all designer tools are available.

Advanced Controls

All Windows controls are included, as well as a web browser, child-displays, doc viewer, and many others. WPF controls, such as scheduler controls, Gantt, or live video cameras, can be added to extend functionality. Legacy Active-X controls can also be used for compatibility.

Deployment Scenarios

FactoryStudio is based on a unified-package architecture, so the server is always the standard FactoryStudio software. However, all FactoryStudio modules such as Scripts, Device, Historian, Database, etc. may be placed on different computers, in a distributed system context. The server computers can run in different Operating Systems, which connects many client visualization stations and allows flexible deployment scenarios.

From Standalone to World-Wide

The FactoryStudio family of products is uniquely designed to provide the most reliable, flexible, and powerful application development platform. You can build an application to run on a small device with very limited amount of I/O, run on a production line or a commercial building, or you can provide information across the globe to those that need it, on any device, anywhere.

The same configuration tool can create applications for desktops, mobile, HTML5, and embedded devices. |

Data Aggregation from multiple locations

FactoryStudio is the perfect platform to collect data from multiple locations and access it at a centralized location. Hundreds to thousands of distributed FactoryStudio nodes provide data acquisition and publish the collected data to a cloud server or to a corporate office.

Multiple User Security

Users can use Application Security, Windows Authentication (Active-Directory), or WS-Federation concurrently, which all map to the same application server.

Learn more at Displays and Clients. |

Symbols and Components

Symbols and Components

Map Symbols to Assets

Create assets and templates based on reusable components with runtime binding, standard graphical visualization, and centralized management

Linking Tags to Symbols

Our platform has many rapid application development tools. One example is the ability to define Categories in which Tags and Symbols can be tightly integrated. Using Categories expedites screen development by specifying graphical symbols to automatically be used in displays simply by copying Tags and pasting them into your displays.

For example, Users can define a default Pump symbol and all of its’ attributes to use in displays. Then by specifying a Tag to have the same Category as the Pump, when the Tag is pasted into the display it comes in as the default Pump symbol for that category. There is simply no need to go through the manual steps of placing individual symbols on the display and assigning the attributes.

Import Objects and XAML

Images and symbols can be imported from the most popular formats used today. XAML standard simplifies automated import of displays from legacy HMI and SCADA system.

Extended Symbol Library

Our platform has its native library of symbols created with properties assigned to them. To help you create the most advanced graphical displays, FactoryStudio was the first software package of its type to also include the SymbolFactory.NET library of over 5,000 vector-based graphics at no charge! This library is installed with every FactoryStudio development package and it is unlimited in terms of how many symbols you use and how many times you use them.

Edit multiple symbols, rows and properties combined |

Diagnostics Tools

Diagnostics Tools

FactoryStudio has a complete set of tools to assist developing, testing, diagnosing, and commissioning your projects for field installation.

Technology Foundation

A solid foundation is required to achieve operational stability. FactoryStudio was designed by carefully selecting secure, efficient, flexible, and modern technologies; all without carrying undesirable legacy baggage.

Project Configuration

For projects that were created with tools from another software, many errors that occur in the field result from undetected configuration errors that occurred during the development of the project. Instead of the trial and error outdated method, FactoryStudio has added many features that target consistency checks and complete configuration verification in the engineering environment.

Test and Field Deployment

Possible errors and famous SCADA viruses, such as Stuxnet, were due to deployment security breaches. FactoryStudio’s design includes specific features to simplify and secure field deployment.

Maintenance and Operations

Operational stability, the number one requirement of most automation systems, is based on a chain that embraces the complete project life cycle: the Selection of Technologies, Project Configuration, Test and Field Deployment, as well as Operations and Maintenance.

• Each configuration row has the date it was created and modified. • A summary view of every change made to each table is available. • Build commands can create project labels and save partial, uncompleted versions. • Publish command creates runtime-only projects with release version control. • FactoryStudio automatically logs who changed what for all project configurations. |